How can you get thermal management and EMC to work together?

This new course will be given by Norbert Engelberts (OTS) and Mart Coenen (EMCMCC). The trainers will draw upon their combined 50 years of engineering knowledge and experience working in the respective fields with many well-known OEMs.

Frequently, thermal management and EMC requirements are contradictory. A better thermal design would readily result in a product that does not satisfy its EMC requirements. And visa versa, focusing on EMC only, the product could fail due to exceeding its thermal requirements.

Here are some topics. We suggest interactivity by bringing your own question for optimal results in the course.

Component level

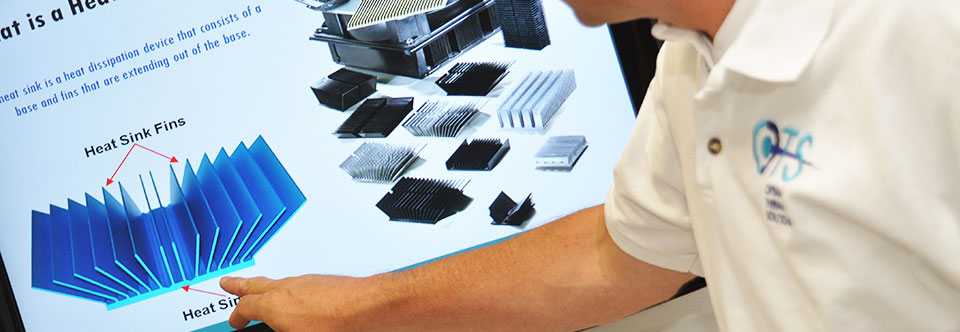

- What is the effect of attaching a heat sink?

- Does a heat sink need to be electrically coupled or can it be floated?

- What are the advantages and disadvantages? In a wireless environment, antennes need to have a specific transmission profile. How should these be placed so that any negative effect of the heat sink is minimized?

PCB level

- How can one make an optimal use of copper layers: earth, power and impedance traces?

- What is the ideal board routing and distance?

- Where vias should be placed so that they still benefit the heat transfer but do not introduce unwanted electromagnetically coupling components?

- How should heat sinks, cold plates and chassis parts, which need to be earthed, still be used for the thermal design?

- How can high frequency noise be limited?

Subrack level

- What are the trades between a grill optimized for EMC and one optimized for thermal? What is the ideal compromise between the two?

- The application of flow guides and/or dummy components: should they be manufactured out of aluminium or FR4? If FR4, with or without copper layers? And should they be coupled to the back plane or front plate?

Rack / Enclosure level

- Inlet and outlet grills and filters: thermal vs EMC?

- Should fans be placed inside or outside the EMC boundary?

- What is the ideal placement of fans with regard to the optimal air flow?

- Ideal cable placement

- How do safety requirements influence your EMC and thermal designs?

This one day course will be conducted at the Telerex Breda and Antwerp offices.

Price: €595,–, excl. VAT – (incl. coffee & lunch). To register, please follow this link.

Dates and locations of all courses / trainings are given on OTS’ calendar.

Please check the presentation Slim Thermisch en EMC compliant design – Coenen-Engelberts – EMC event Telerex